How to Build a Storage Cabinet with Swing-out Shelves and Sliding Doors

Tools and materials (affiliate links)

- 2-½ sheets of ¾” maple plywood

- ½ sheet of ½” maple plywood

- 13/16″ maple edge banding

- (4) 2″ butt hinges

- (4) ¾” diameter Finger pulls

- (4) ¼” diameter aluminum brass rods

- (24) Adjustable shelf pins

- 1-½” #8 flat head wood screws

- 1-¼” pocket screws

- 1-¾” flat head Tapcon screws*

*If mounting to cinder block walls; Otherwise use appropriate wall anchors (secure to studs).

- Table saw

- Track saw

- Router table or handheld router

- ½” straight router bit

- Hacksaw

- Drill/Driver

- Countersink bit with depth stop

- 90-degree corner clamp squares

- Pocket hole jig

- Shelf pin jig

- Forstner bits (¼” & ¾”)

- Edge banding trimmer tool

- J-roller (for edge banding)

- Level

- Hammer drill*

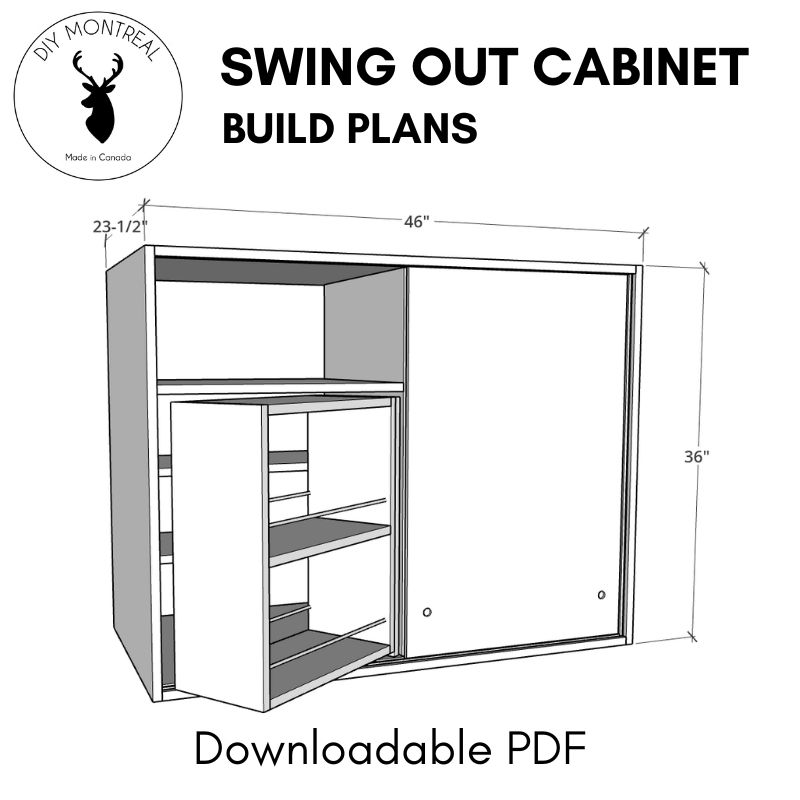

Get the plans (click image blow)

Building a Custom Shop Cabinet with Swing-out Shelves and Sliding Doors

Transforming garage space into an organized haven for tools can be challenging. I recently tackled this by designing and building a unique storage cabinet. This project was born from my need to relocate small power tools from the basement to the garage, maximizing storage with an extra-deep wall cabinet featuring sliding doors and swing-out shelves.

Step-by-Step Process:

1. Breaking Down Plywood: Using ¾ inch maple plywood, I started by having the large sheets cut in half at the store to fit in my SUV. Back in the shop, I used a track saw for initial cuts and a table saw for precise final cuts.

2. Cutting Sliding Door Tracks: I cut tracks into the top, bottom, and sides of the cabinet for the sliding doors using a router table. Ensuring the top track is deeper allows easy installation and removal of doors.

3. Applying Edge Banding: For a polished look, I edge banded all front-facing plywood edges using iron-on edge banding. This step is optional but gives a professional finish.

4. Adding Shelf Pin Holes: Using a jig, I added shelf pin holes for adjustable shelves. Ensuring accurate and consistent spacing is crucial for functionality.

5. Cabinet Assembly: Assembling the cabinet with screws, I used corner clamps to ensure everything was square. I opted for a French cleat system for wall mounting, ensuring a secure and level installation.

6. Installing Swing-Out Shelves: Building swing-out shelves with pocket screws and brass rods, I ensured they would support the weight of tools without sagging.

7. Creating Sliding Doors: Using ½ inch plywood, I crafted the sliding doors, opting for a thickness that balances durability and ease of use. Finger pulls were added for easy opening and closing.

Challenges and Adaptations:

Initially, my design included full-height swing-out shelves, but garage door tracks required a change to sliding doors. Despite the adjustments, the cabinet maximizes storage and accessibility, fitting perfectly above my router table.

Conclusion:

This project highlights the importance of adaptability in DIY woodworking. The result is a highly functional and organized storage solution that fits seamlessly into the garage space. For those interested in replicating this project, detailed plans and a list of tools used are available.

By following these steps and embracing flexibility, you can create custom storage solutions tailored to your space and needs.