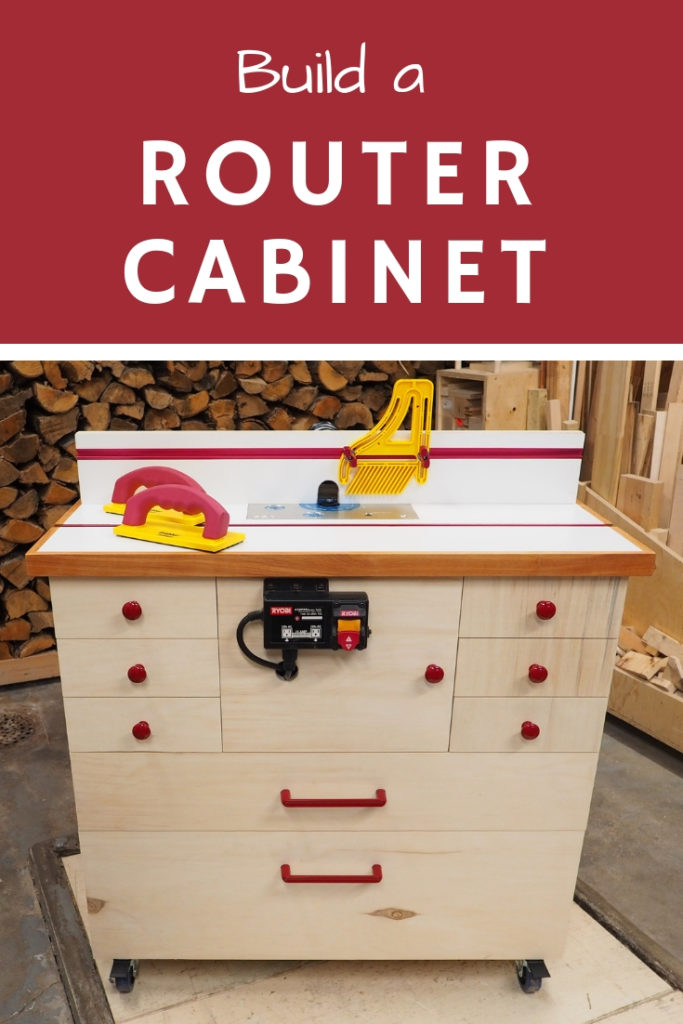

I recently got my hands on a Pro Lift router lift from Rockler and decided to build my own router table top. If you haven’t seen that yet, you can read it here or watch the video. In part 2 of this router table build, I tackled making the router cabinet for the base.

Click here to SUBSCRIBE to my YouTube channel for more DIY videos!

Here are the tools & materials you’ll need:

GET THE PLANS

MATERIALS

- (1-1/2 sheets) 3/4″ plywood

- (1 sheet) 1/2″ plywood

- (1 pair) Euro hinges – frameless ½ overlay

- (2 pairs) 20″ Drawer slides

- (4) 3″ locking caster wheels

- (16) 1″ lag screws

- Pocket screws (1-¼”)

- (7) Drawer knobs

- (2) Drawer pulls

- 4″ dust port

- Red spray paint

- Safety paddle switch

TOOLS

- K4 pocket hole jig

- Kreg drawer slide jig

- Kreg Hinge jig

- Kreg cabinet hardware jig

- Mini palm driver

- Kreg Quick clamp

- Spring clamp

- Jigsaw

- Countersink drill bits

- Weldbond

- Cordless Nail gun

How to Build a Router Cabinet

Like most projects, this one started off at the lumber store. Since I can’t fit a full sheet of plywood into my car, I had mine cut down to more manageable sizes at the store, then finished making cuts in the shop. I cut all the parts following the cutting diagram in the build plans.

Assemble Cabinet

I used my Kreg K4 pocket hole system to pre-drill all of the pocket holes I’ll need to assemble this project.

With all the holes pre-drilled, assembly was easy. I started by attaching the back panel to both sides using some 1-1/4″ pocket screws. Before this step, it’s a good idea to trace a line 12 inches down from the top on a 3 sides.

Next, I inserted the middle divider that I butted up to the references lines I drew in the step above. I used some spring clamps to help hold it in place while I secured it from underneath with some pocket screws.

I then slipped the bottom panel underneath and screwed down the cabinet on all 3 sides.

Make Lower Drawers

To figure out the size of my drawers, I first measured the width of the opening then subtracted 1 inch to account for the thickness of the drawers slides I’m using. I used 1/2-inch plywood to make the drawer boxes. I made one deep drawer and one shallow drawer.

To assemble the drawers, I first applied some glue to the seams and used brad nails to help hold the box together while I screwed in some pocket screws.

With the slides assembled, I applied glue all along the bottom and dropped in the bottom panel that I secured with brad nails.

This was my first time working with drawer slides but the process is pretty simple. For the bottom one you’ll want to use a small spacer to raise the drawer up a bit, then set the drawer slide an eighth of an inch back. Holding it firmly in place, just pull the slide out and find the screw holes to secure it to the cabinet.

Next you can pull the drawer out just a bit along with the bottom spacer and attach the slides to the drawer, then work your way back to the following screws.

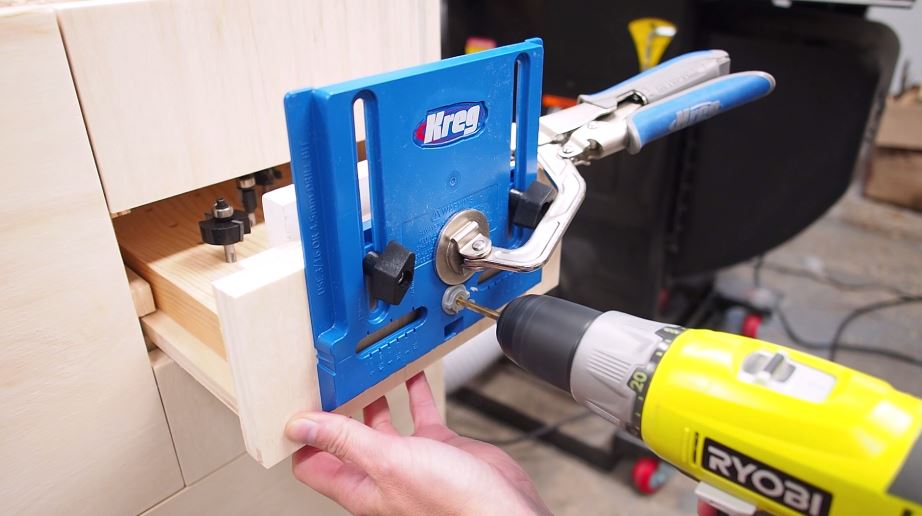

For the upper drawer, I repeated the process using my Kreg drawer slide jig which made the job easy.

Attach Drawer Faces

To attach the drawer faces, I started with the bottom so I could use the table to line up the bottom with the cabinet. I clamped the face to the drawer box securely, then slid out the drawer and used a countersink bit to drill some holes in from the back, then secured the face to the drawers with some screws.

I repeated the same process for the upper drawer, but used washers as a spacer between both drawers.

Casters

Before the cabinet gets too heavy, I decided to move it to the floor. I first however flipped it on its back and attached some 3 inch caster wheels using some lag screws.

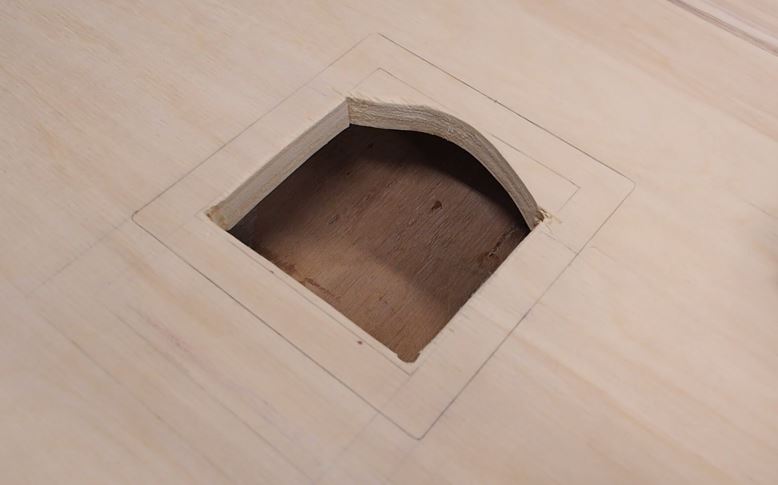

Dust port

My router table top has a port in the fence for dust collection, but I also want to collect the dust that falls below the table, so I’m adding a 4 inch dust port to the back of the cabinet. After moving the cabinet down to the floor, I traced the out the port (both inside & out) and used my jigsaw to cut out the hole.

I used some Weldbond glue to create a seal and attached it to the cabinet with some screws.

Upper Mini Drawers

For the top part of the cabinet, I wanted to add small drawers, but decided to go with simple wooden slides that I nailed into place with my brad nailer.

I repeated the same pattern on a second panel, then checked to make sure my drawer bottoms would fit before securing the panel to the cabinet with some pocket screws.

I then repeated the same thing on the other side of the cabinet.

Access Door

The top middle section is going to be a door so I can easily access my router from underneath if I have to. I used a hinge jig with a 35mm Forstner bit to countersink the hinges.

I loosely attached the fasteners to the cabinet leaving some wiggle room.

Using washers as spacers on the bottom, I mounted the door, and made the final adjustments.

Hardware

Okay, back to my top drawers, I added these blocks as faux fronts, which are basically just so I’ll have something to attach the drawer fronts to.

Using my trusty washers to get the spacing just right, both on the bottom and on the side, I clamped on the face, drilled some countersunk holes from the back, and secured the face with some screws. After that it was rinse and repeat for all 6 drawers.

To attach the knobs, I used this Kreg drawer pull jig to help place the knobs consistently.

If you’re wondering how my hardware went from nickel to red, I ended up removing them and spray painting them with Regal Red spray paint, just because I liked the look better.

Drawer Trays

I’m not sure what I’ll use all my upper drawers for yet, but I decided to fit one of them with a router bit holder I made out of a 2×8 by drilling a bunch of quarter inch holes into it, since my bits all have quarter inch shanks.

For another drawer I decided to make a simple box where I’ll be able to store the main tools I’ll use for the table, like the lift handle and wrenches.

Attach Table Top

In the final stretch now, it’s time to attach the table top. If you haven’t seen part 1 where I show how I built this table top, be sure to check that out. After lining up the top to where I wanted it, I attached it from underneath with pocket screws using the pre-drilled holes I had made.

Install Safety Switch

A router table really isn’t complete without an external switch. After mounting the switch to the door on the side closest to the hinge, I used a Forstner bit to make a hole and feed the wires through.