There are several ways to cut a hexagon out of wood. You could use a table saw with a miter gauge, a bandsaw, miter saw, and so on. When you want to batch out several hexagons and make them all the exact same, it can get tricky. That’s why I decided to build a simple hexagon cutting jig.

Materials Used

- 3/4 inch Baltic Birch Plywood

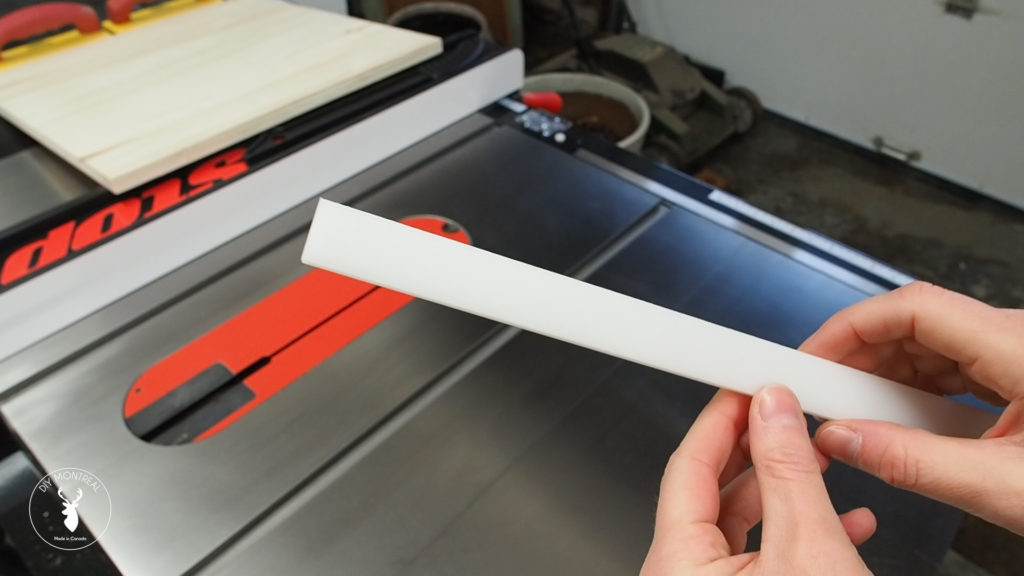

- UHMW runner

- Toggle clamp

- Protractor

- Hot glue gun

- Double-sided tape

- Super Glue

- Paste Wax

How to Make a Hexagon Cutting Jig

I began by making a basic sled using ¾ inch baltic birch plywood. I’m using a runner made from UHMW, which is a type of plastic. These runners are machined to fit the miter slot perfectly so I don’t have to fuss with it. Plus they won’t be affected by changes in temperature or humidity.

In the picture below, I’ve lined up the fence with where I want the board to sit vis-Ã -vis the blade. You’ll notice that the runners are shorter than the board but that’s okay for this particular sled since it won’t be moving off the front or back of the table. I’ve also skewed the sled to the left because the bulk of the jig will be on that side. Locking my fence into position I could now remove the board and drop in the runners.

Since the runners are aren’t as deep as the miter slots I’ll need to raise them up with some dimes so they’ll touch the plywood when I lay it on top.

With the runners in place, I added a few dabs of super glue then dropped the plywood into position up against the fence.

Then after holding it down for a minute, I could pull off the board.

With the runners temporarily glued in place, I used a countersink bit to drill some pilot holes into the runners. I could then permanently attach the runners with some screws, making sure the screw heads were fully sunken into the runners.

It helps to apply some paste wax to the bottom of the sled, covering all the wood parts with a thin coat. This will really help the sled slide a lot smoother, with less friction.

After a test fit, I cut the kerf line in the sled, making sure to only go about half way, no more.

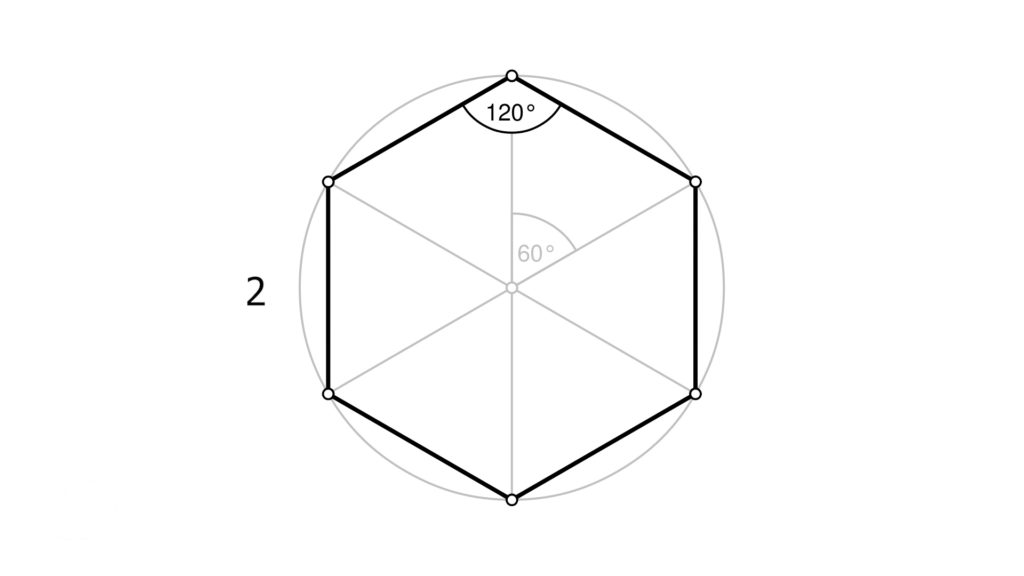

So here’s what you need to know about a hexagon. It has 6 sides and all the outside angles are 120 degrees. I want to make one that’s 2 inches on each side.

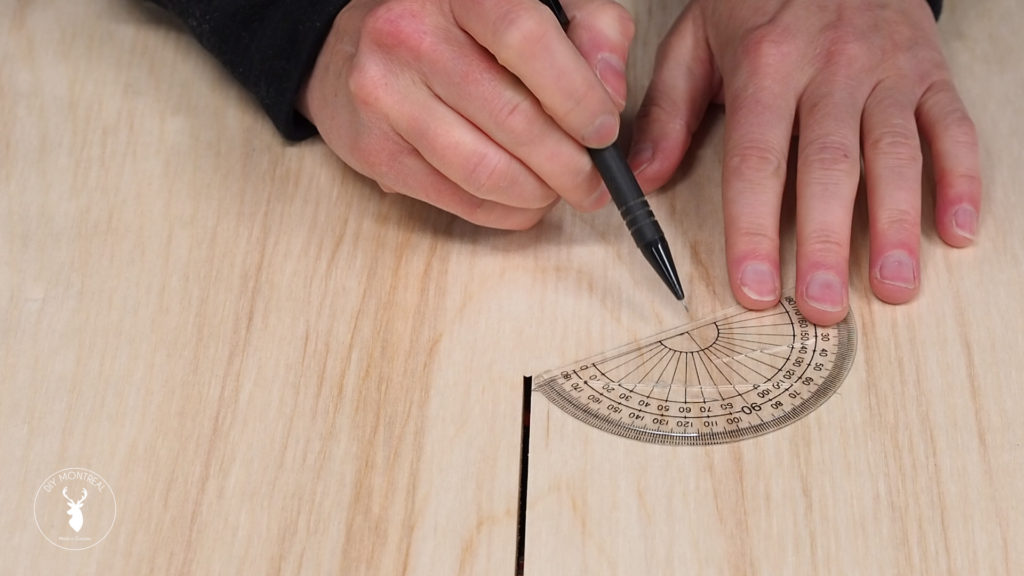

I started by making a small notch next to the kerf line and this will just be my reference starting point. You can use any type of protractor for this, like one of these, or even a digital angle gauge which would be more accurate. Another good option (I should have used) would be to trace the Hexagon using a the compass method (see method described in this video)

I set the protractor on the edge of the kerf line, centered with the reference mark and then marked out 120 degrees. Then I simply connected the dots.

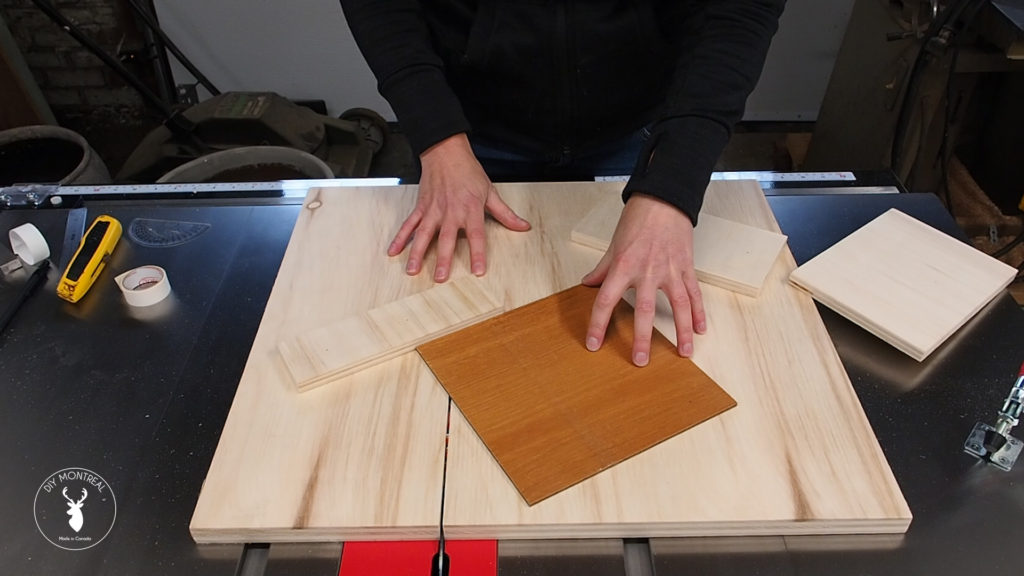

You’ll need a few small pieces of plywood for the next part. On the first one I measured 2 inches since that’s the size of the Hexagon I want. I positioned it so the 2 inch marking lined up with the kerf line and marked off the other end. Using that mark as a starting point, I made another mark at 120 degrees.

Note that it can be tricky to get the angles just right, so you may need to tweak them a little bit to get the jig perfectly dialed in. If I were to build this again, I would probably actually pick up a sample hexagon ceramic tile or something that I could use as a template to get the angles and the dimensions just right.

Anyways, after connecting those dots, I used my hot glue gun to secure a piece of plywood up against the line, lining up the corner with my the point of the hexagon that I traced out.

Now the other side is a little different. I’m going to start off by securing a small piece of plywood using some double sided tape so I can pull it off afterwards, again butting it up against the line I traced out.

I could then place another piece of plywood up to that one and secure it using some hot glue. Once that had dried, I could pull up the front piece.

Okay, so let me explain myself a little bit. The reason this front piece needs to be removable is for the first cut. When you start off with a square board you’ll need room to lay it down and make the cut.

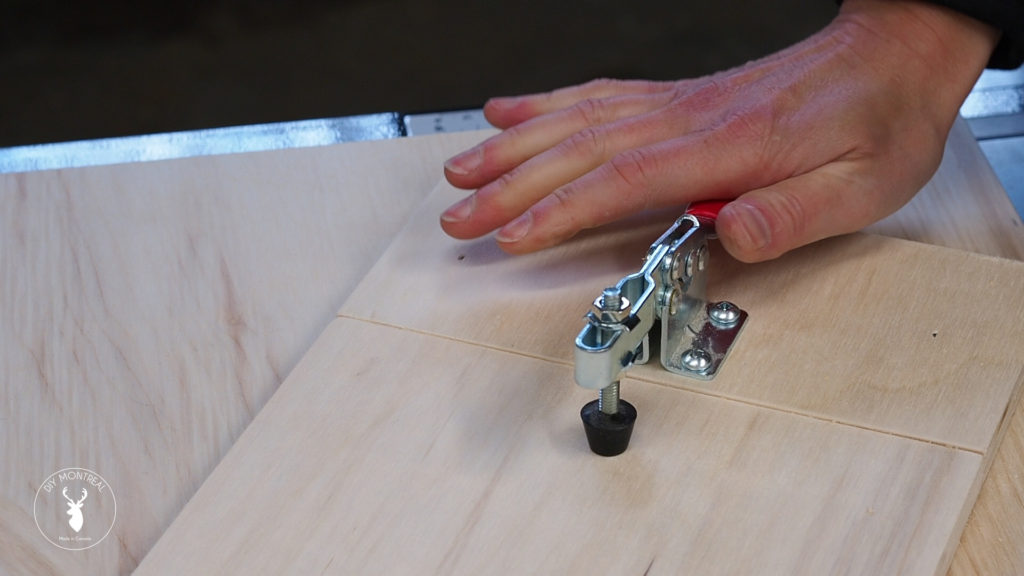

That’s where this toggle clamp comes into play. I’m going to use this as a simple way to be able to easily remove the board when I don’t need it, or on the contrary lock it down when I do need it.

And that’s pretty much it! Well, actually I do recommend adding a back fence just to make the sled easier to manoeuvre.

Below you’ll see me testing out the jig with some wood scraps, not really concerned about wastage. When using the jig it’s recommended to cut down wood blanks close to final size to limit such waste.

Other than that, you start with the block removed and make the first cut. After that put the block back into position and lock it down. Then simply rotate the blank clockwise as you work your way around.