When you work in a small shop or a garage, it can be easy to overlook dust collection. That being said, when you work in a small space, the air can quickly saturate with fine dust particles, which can be hazardous. In this article, I’ll cover the various dust collection options I use in my home shop, and different dust collection solutions for small shops.

Dust Collection for Small Shop

Shop Vacs

The first thing almost any hobbyist acquires to help with dust control is a shop vac. These come in various brands and sizes, up to 50L with 6.5 peak HP on the higher end. I have compact Stanley wet/dry 5 gallon model that doesn’t take up too much space.

Shop vacs tend to be loud and are notorious for spitting out fine dust. You may not see it, but most shop vac filters aren’t equipped to capture fine dust, and ultimately just fill the air with hazardous fine particles. On some models you can upgrade for a HEPA filter, which can filter up to 99.97% of fine particles down to 0.3 microns I definitely recommend upgrading your filter if it’s a possibility for your model. It’s well worth the investment.

Dust Cyclone

Another upgrade you can make to your shop vac is to add a dust cyclone, like the Oneida Dust Deputy. The external cyclone helps separate the larger chips from the fine dust. The larger shavings will end up in a bucket, while only the fine dust will go into the vacuum. This will not only help prevent clogging up you shop vac filter, but it will also cause the system to run more efficiently and keep it from loosing suction over time.

I have a dedicated Ridgid vacuum with a dust cyclone under my miter saw that is automated with an iVac switch. That way the shop vac automatically turns on whenever I use my miter saw, and automatically turns off 6 seconds after I’m done.

While the cyclone definitely helps maximize suction on my shop vac, not all the dust is captured by the system. As you have probably experienced yourself, miter saw dust collection is notoriously problematic. That’s why I added a dust shroud around my miter saw to help trap any airborne sawdust. The box is equipped with sliding doors, which makes it easy to quickly open them up if I need to make a miter cut.

I have a full video tutorial on my miter saw dust collection if you want to check it out.

Dust Mask or Respirator

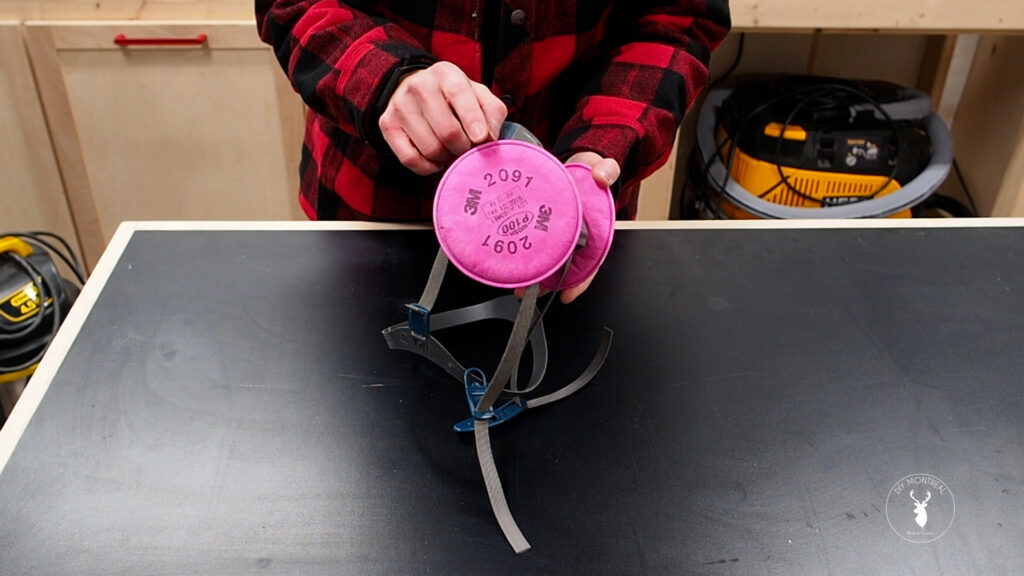

Whether you have a fully plumbed dust collector or no dust collection at all, I highly recommend investing in a reusable dust mask, like this half face respirator from 3M. This is the one I’ve been using for years. You can change the filters as needed, and they have a whole range for different applications. I typically use their P100 filters, namely the 2091 or 2097 filters.

When worn correctly (should be a tight fit around the face) the P100 filters will filter out 99.9% of particles (like sawdust) down to 0.3 micron. I find this mask comfortable enough to wear for long periods without being a nuisance. I wear it anytime I’m making dust, even if I’m using some method of dust collection. Sawdust is known to cause all sorts of health issues, ranging from asthma and allergies, to polyps and lung cancer, and I personally don’t want to be breathing in any sawdust if I can avoid it.

Air Quality Monitor

If you’re one of those people who can’t be bothered to wear a mask in the shop or needs a reminder, I highly recommend getting an air quality monitor. After doing extensive research and trying out a few that weren’t great, I landed on the Dylos Pro 1100 Laser Particle Counter.

This air quality monitor continuously measures both large particles (>2.5 microns) as well as fine particles (down to 0.5 micron). As soon as the numbers start to rise, I know it’s time to put on my respirator and fire up my overhead air filtration unit.

Overhead Air Filtration Unit

Even if you are capturing most of the dust at the source with a shop vac or dust collector, sawdust can easily saturate the air in a small shop. A good way of dealing with this is adding overhead air filtration, like this WEN 3-speed air filtration unit. With a max of 400 CFM, it can easily scrub the air in my 250 sf shop multiple times per hour.

The unit has both an inner filter (1 micron) and outer filter (5 microns) for efficient filtration. I keep extra filters on hand to swap them out as they get dirty fast. The unit comes with a remote control and timer function, so I can set it to run for an hour after I leave my shop.

Dust Collector

When woodworkers think “Dust Collection”, a dust collector is usually what comes to mind. This is however a tool that may be overlooked by hobbyists. I know I never thought I’d get a dust collector in my small workshop. In fact, most of my first tools didn’t even have dust ports, so I couldn’t have used a dust collector even if I wanted to.

After I upgraded a few of my tools, like my Sawstop Table Saw and Dewalt Planer, I realized I needed to seriously consider getting a dust collector. You see, these tools actually need dust collection in order to run efficiently. Most will even specify the minimum CFM requirements in the manual. My table saw requires a minimum of 350 CFM, while my planer requires 400 CFM.

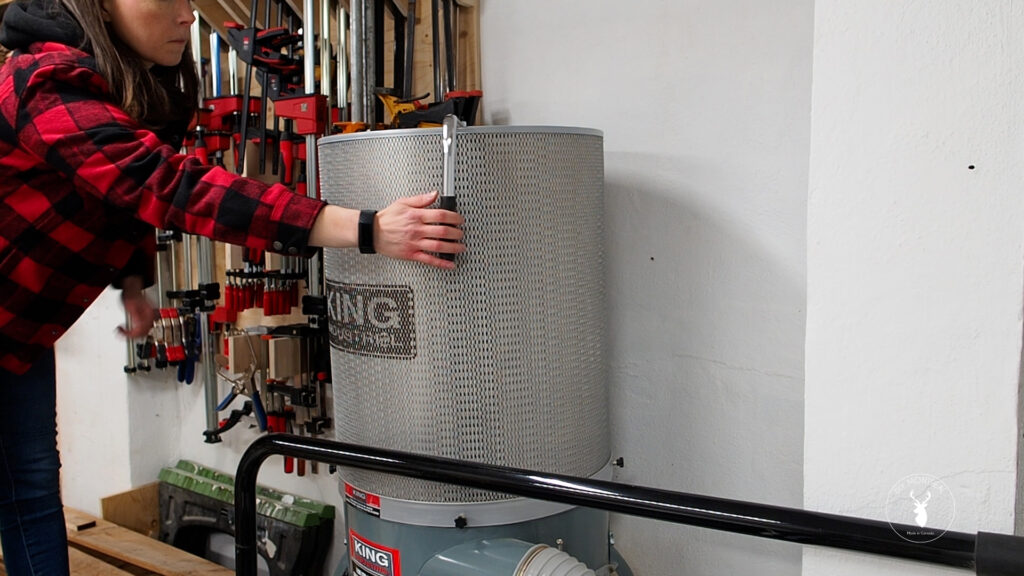

A couple years ago, I pulled the trigger and went for the King Canada KC-3105C/KDCF-3500 with canister filter. Below are some of the considerations that lead me to choose this dust collector for my small shop.

CFM

While you may think getting a dust collector with the minimum CFM to cover your tool requirements will be enough, think again. Keep in mind that many factors affect suction on a dust collector including, distance to the tool, use of flex hose vs. rigid ducting, elbows or curves, and even the filter itself. As such, aim for at least double the CFM of your most demanding tool. I went with a 1200 CFM model and it’s been working magnificently in my 250 sf shop.

Bag Filter vs Canister Filter

Most dust collectors come with bag filters, but you get also get canister filters. The canister is rigid with pleated filters on the inside. I was dead set on getting a canister filter. It’s slightly more expensive than a bag, but totally worth it. I’ll just say that if you are going to get a bag filter, be sure to check the micron rating and avoid those in the 5 micron range. Instead, aim for 1 micron or less. Otherwise your dust collector will just be spitting out fine hazardous dust into you shop.

Canister filters are known to have better airflow than bag filters that won’t affect suction as much as a bag filters do. In fact, canisters come with a rubber flapper inside. By turning the external handle, you can rotate the flapper and knock any caked-on sawdust off the filter and down into the bag. This prevents the filter from clogging and keeps the dust collector running as efficiently as possible. The filter is also really easy to clean. Whenever I empty out my dust collector, I remove the filter and clean the inside with my shop vac, which only take a few minutes.

Footprint

Dust collectors come in various sizes, form compact wall models to double bag floor models. Bigger models will typically have greater CFM, but also occupy more floor space.

Electrical

Larger models will also typically require more power. My dust collector runs on 120v and plugs into a standard 15 amp outlet, but also has the option to be converted to 240v. Some models only run on 240v, which means you’ll need to hire an electrician to install a 240v outlet if you’re not already set up in your shop.

It’s also worth pointing out that dust collectors pull a lot of amps (mine pulls 12 amps). If you have 15 amp circuits like I do, you’ll need to run your dust collector off a separate circuit than your tools so the breaker won’t trip.

Dust Port

Depending on how you connect your tools to your dust collector, you’ll want to be mindful of the ports coming out of the machine. My dust collector came equipped with a dual port (6 inch port that splits into two 4 inch ports), which is perfect for my needs. I have one port dedicated to my table saw with a permanent hook up. On the other port I have a blue expansion hose that I can pull out and connect to any of the other large stationary tools in my shop, like my planer, bandsaw or router table. Each port is equipped with a blast gate that I open or close depending on which tool I’m using.

Dust Extractor

The most recent addition to my dust collection arsenal is my Mirka Dust Extractor. There’s a lot of confusion out there on what the difference between a shop vac and a dust extractor is, and I can totally see why. I find it quite confusing myself!

The advantages of a dust extractor over a shop vac that I can see are:

- More quiet

- HEPA filter

- Better suction

- Filter won’t clog

Of course the tradeoff is that dust extractors are more expensive than your typical shop vac, but I can definitely see why after using mine for a few months now. I use my dust extractor with many of my handheld power tools that have dust ports, like my track saw and biscuit joiner, but my orbital sander benefits from this the most. Sanding is notoriously messy and causes tons or airborne dust, but the dust extractor does an exceptional job at controlling this.

So Many Dust Collection Options

No matter what you choose, know that there are several options for controlling dust in a workshop, which is especially important in small spaces. If you live in a warm climate, by all means open up the garage door and let in some fresh air! That right there is the easiest and most cost-effective solution.

For budget conscious woodworkers, using an affordable respirator may be all you need if you don’t mind sweeping up. Upgrading your shop vac filter with a HEPA filter and adding an external cyclone will also go a long way.

Whatever you decide, remember to be safe and protect your lungs!