Working from home has become more popular than ever. Even though I’ve been teleworking for over a year now, I’ve been doing so from everywhere but my home office. The kitchen, the couch, the bed, you name it. The truth is my home office looks more like a storage unit than anything else.

Today, I’m finally tackling my DIY desk top build to finish my desk and ultimately have a suitable workspace. In this tutorial, I’ll show you how to make a solid wood desk top out of rough sawn ash wood. My desk is going to be huge: over 7 feet long! With plenty of storage space and leg room.

DIY Desk Top Build

After cleaning out my office, I could finally get my newly built base cabinets into position. I adjusted the leveling feet until the cabinets were flush and I could then clamp them together and attach them with some screws.

After checking for level, I positioned and leveled the third cabinet, then popped in all the drawers. If you’re interested in seeing how I built these, you can check out the cabinet build video or the drawer cabinet build plans for more details.

Tools & Materials

- K Body clamps https://amzn.to/34oOc1X

- GearKlamps https://amzn.to/3bZjVe6

- Mini F-clamps https://amzn.to/3vxoX9u

- Roller stand https://amzn.to/3oWA2hW

- Push blocks https://amzn.to/3fujxXa

- Machinist square https://amzn.to/3fpK48f

- Featherboard https://amzn.to/3fsKjiJ

- Mirka dustless sander https://amzn.to/3upVYmJ

- Sanding disks https://amzn.to/3p46fUD

- Trim router https://amzn.to/34q0JSQ

- Glu-bot bottle https://amzn.to/3bVnFgQ

- Glue brush https://amzn.to/3c1vFgt

- Glue scraper https://amzn.to/3fUkMy7

- Tack cloth https://amzn.to/34pjIwO

- Osmo Polyx-oil https://amzn.to/34qRku4

- Card spreader https://amzn.to/3uqQ84I

- Nitrile gloves https://amzn.to/2Tk0BSt

- Osmo easy pads https://amzn.to/3ut81jg

How to Make a Solid Wood Desk Top

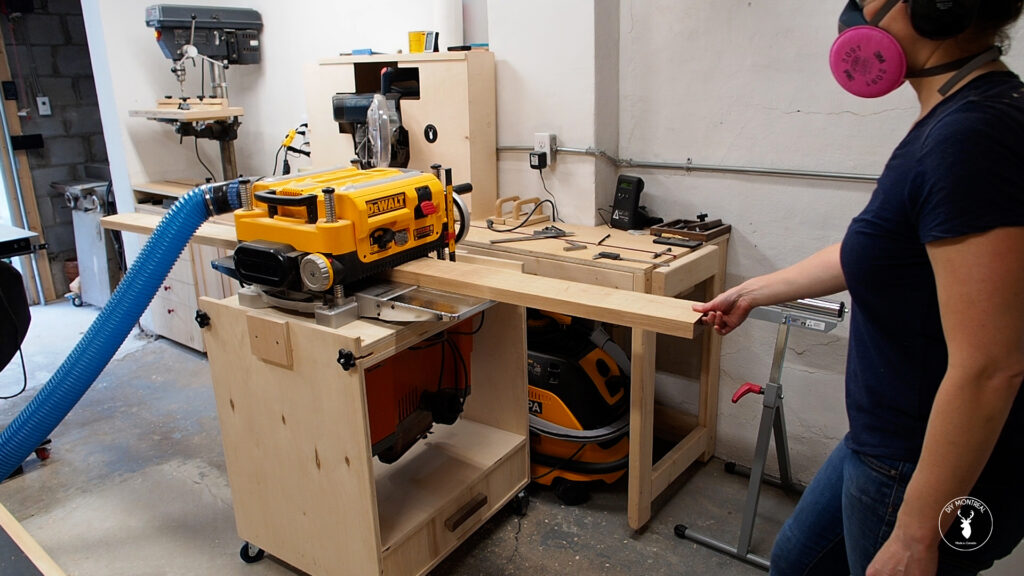

The biggest challenge in making this solid wood desk top is the limited space I have in my workshop. There’s not much room to work on such a large project, but that’s why most of my tools are on wheels, so I can move things out of the way and make room to use my tools.

I’m starting with 5/4 rough sawn ash that I’ll mill on all 4 sides. This is my first time milling such long boards, and I quickly realized that my jointer wasn’t long enough to support them and be able to work safely. I picked up a pair of roller stands in order to support the wood both on the infeed and on the outfeed. Using a straightedge I could line them up with the jointer beds and get to work.

The Lumber Milling Process

I’ll start by flattening one face on the jointer, putting the cupped face down and keeping the pressure on the outfeed side. It took several passes until the face was flat and let me tell you, working with long solid wood boards is quite the workout!

With one face flat, I can flip that face up against my jointer’s fence in order to flatten and square one edge. I checked the edge for square, then could move over to the planer to flatten the opposite face.

Feeding each board one after the other, I could progressively lower the cutterhead until all the boards were flat and had the same thickness. I was hoping to end up with 1-inch in thickness and ultimately ended up just a hair below the 1-inch mark. Not bad.

With all the boards milled to their final thickness, the last step is to rip them to their final width at the table saw, running the jointed edge up against the fence. I won’t lie, getting big boards perfectly square left me a little frustrated when I realized that there were gaps in my joints. Nevertheless, after flipping a few boards around, I managed to close most of the gaps and get a decent fit.

Glue up

Alright, it’s time to get these boards glued up! After feeling how heavy each of these boards was, I quickly realized that once this desk top was assembled, it would be really heavy. So instead of figuring out a way to carry it up two flights once it was all done, I decided to assemble it directly in my home office.

Glue ups can definitely stress me out, so to make it as stress-free as possible, I got everything ready. It’s times like theses that I’m grateful to have all my Bessey K-Body parallel clamps. They make a huge difference in keeping panels flat and getting tight seams without any gaps.

The Glue up Process

All right, so here’s my glue up process in a nutshell. First I apply a thick bead of glue to one edge on 4 out of my 5 boards, getting full coverage using a glue brush. You don’t need biscuits for strength, but if you like them, they can help with alignment.

I can now lay my boards flat and start closing the clamps without tightening just yet, just a light twist until they start to bite.

I’ll then add some mini F-clamps to both ends, using one per seam. This will make sure the boards stay aligned and flat. Again, I’m not really tightening at this point. I can then go back and start tightening my clamps, checking that each board stays flat and the seams look good.

For extra insurance, I’ll use clamping cauls in the middle to make sure the panel stayed dead flat. These cauls are slightly tapered from the mid-point towards the ends. I’ve put clear packing tape on the bottom edge so it won’t stick to the glue.

I can now do a final tightening of all my clamps. I almost forgot to add clamps to the short section that overhangs my bench, so I’ll add them on top. Alright, time to let this dry, but I won’t go too far just yet.

Don’t Let the Glue Harden!

After about 30 minutes, I can come back to scrape off the glue while it’s still soft. I finally found the perfect tool for this. It’s a razor blade scraper but with plastic blades that won’t damage the wood! In the past I’ve tried wiping off the glue with a wet rag. I’ve also tried waiting until it dried and using a chisel. Ultimately I got really frustrated with both of those methods.

Once all the glue was scraped away, I let the top cure in the clamps for a full 24 hours.

Sanding and Prep

Now comes the fun task of sanding, starting with 80-grit to remove any remaining glue and get it nice and flat. This process takes time, so don’t rush it. It me a good 15 minutes to get through one side. I then flipped it over and hit the other side, making sure to hit the the edges too.

With the top now flat, I’ll pause the sanding at this point to work on shaping the desk. I finally get to try out my new track saw to square off the ends and trim the desk to its final size. Of course, if you don’t have a track saw, you can also use a circular saw with a homemade guide rail.

Next I’ll use my trim router with a small round over bit on all the edges. I’m rounding over the edges ever so slightly, just enough to knock off the sharpness and break the edges. You could also do this with a block plane or even just sand the edges.

All right, time to get back to sanding. Did you know there was a simple rule when going up in grits? Never increase by more than 50%. So if you’re starting at 80-grit, plus 50% is 120. Plus 50% is 180. Plus 50% is up to 270, but I’ll stop at 220. If you skip ahead any faster, you’ll likely see swirl marks in your finish.

Finishing

I’m going to finish this top with Osmo Polyx-oil but I first vacuumed the entire room to avoid dust contamination. Then I can wipe down the desk top using a tack cloth to catch any remaining dust nibs.

I’ve seen different methods to apply Osmo either with a roller or a pad, but I want to try using a plastic card spreader. It takes a little getting used to, but ultimately I find that it’s really easy to spread the finish around in a thin even coat. Next you’ll want to wipe up any excess with a lint-free cloth. When I was done, I used another clean Osmo easy pad to wipe down the top again. I applied 2 coats to the bottom face, let it dry, then flipped it over to work on the top face.

Installation

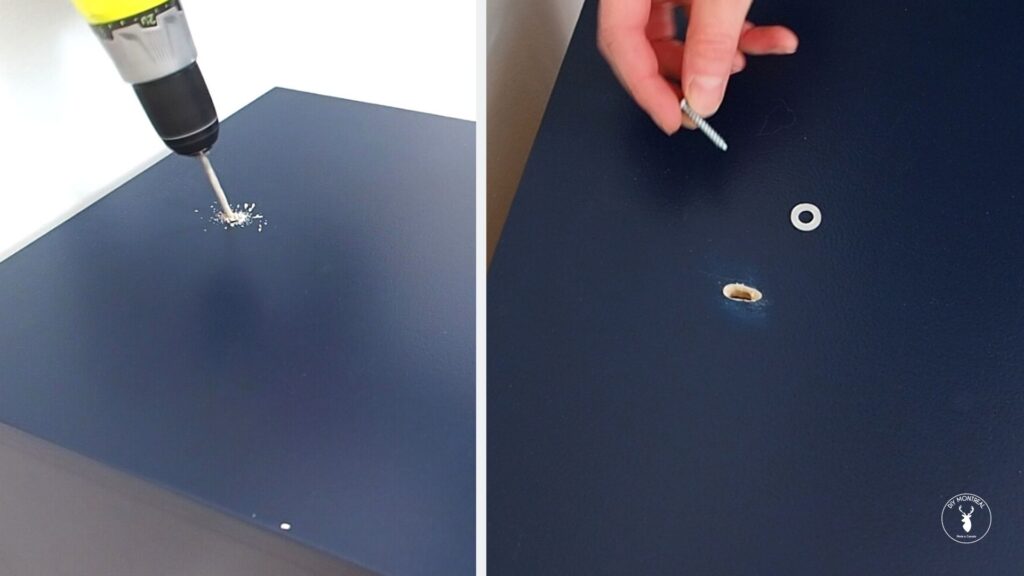

Ever since I started planning this build, I’ve questioned whether or not I would attach the top to the base cabinets. Now that it’s built, I’m not sure that’s really necessary. That being said, I figure if I don’t do it now, I’ll never do it. I’m going to screw the desk top down from inside the cabinets, up into the desk. But if I just drive in screws without allowing for wood movement, the desk top will most likely end up cracking over time. So instead, I’m going to make elongated holes at the back so the screws can move with the wood when it expands and contracts.

All that’s left is to get the top back into position, drive the screws and this desk will be ready to use. I’m so excited to finally have a big desk with plenty of storage, where I can store all my audio & video gear and work on editing my videos.