With summer on the horizon, and most of us spending a lot of time at home right now, I wanted to design a lounger that would allow me to enjoy the sun or read a book out on my deck. I wanted something compact that I could easily store away when not in use. That’s how I came up with this deck wedge that folds flat for easy storage, and you can pretty much set it down anywhere you want.

Materials used

- Cedar wood https://amzn.to/3avzYNi

- Wood dowel

- Pocket screws https://amzn.to/3cHy4dU

- Carriage bolts https://amzn.to/355ci1d

- Nylon lock nuts https://amzn.to/3azrRzg

- Teak oil https://amzn.to/36t1Uk0

Tools Used

- Belt/Spindle Sander https://amzn.to/2uVsW54

- Router table build http://bit.ly/RouterTableSeries

- Router bit (roundover) https://amzn.to/2MDcYBG

- Countersink bit set https://amzn.to/3aOE2JE

- Forstner bits https://amzn.to/2Rht87h

- Center line scriber https://amzn.to/2VFaN70

Get the Plans

How to Build a Sun Wedge / Semi-chaise Lounge

With the COVID-19 lockdown still in full force, I turned to my lumber rack to see what materials I had on hand and what I could potentially build out of them. I set my sights on some leftover cedar that was donated to me by a friend, because of course, I’ve become that person that everyone offloads their wood scraps on. And, well, I willfully accept them.

I started by squaring up the end of each board, then set my stop block so I could batch out evenly sized pieces. I went back and forth between the table saw and miter saw until all my pieces were cut to size, ultimately ending up with 6 long thin pieces and 10 wider short pieces.

It’s been a while since I used my homemade router table and this is the perfect project to put it to use. I want to soften all the board edges so I grabbed a round over bit and set it in the router, and adjusted the fence so that the bearing was just kissing a straight edge.

It’s best to start with the ends of the boards since end grain is likely to tear out, and by doing it first, you can clean it up later when running the board along the long edge. I’m also using a sacrificial trailer board which will reduce tear out significantly. It also helps stabilize the board and hold it perpendicular to the fence.

After doing all of the ends I moved onto rounding over the long edges. When all is said and done, all of the edges are round and smooth, and just looks a little more polished and professional.

I found a circular object the same width as my board and used it to trace out a semi circle on one end of each thin long board. I then took it over to my belt sander and slowly sanded away the corners, progressively sculpting until I reached the line and was left with a rounded edge, and this repeated for all 6 pieces.

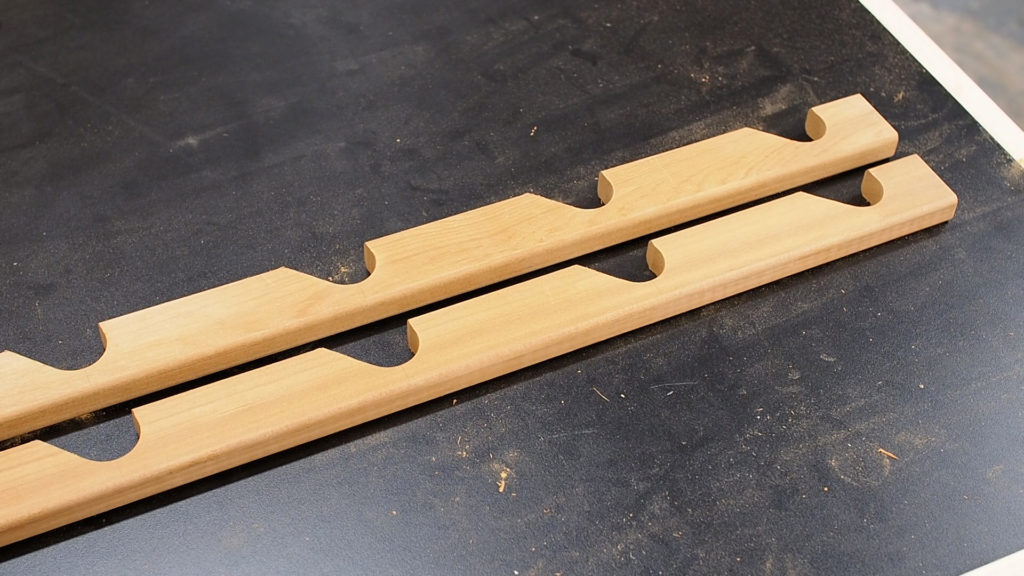

Next I need to make hooked slats for the adjustable back. I started by making evenly spaced markings and then transferred those over to the second piece. I then measured half an inch inwards and used an awl to punch a pilot hole. I could then use a Forstner bit to drill the 4 holes all the way through.

To shape the slots the way I want them, I used a square on one side to make a perpendicular line and used the 45 degree edge of my square to make a line on the other side.

If I had a bandsaw I might have used it to make these cuts, but I used a shortcut and decided I could just shape the slots using my sander with a spindle attachment. Just as before, I slowly sanded away, progressively shaping the wood until I reached the lines and I was left with the 4 sculpted hooks.

To make the pieces that will support the back slats, I first marked a line down the center of the back of the slat, then measured and marked evenly spaced reference marks. I used the drill press so I could control the depth, and used a Forster bit to countersink the holes that will be used for the screws.

After that, I could use a regular bit to drill all the way through, using a bit large enough to allow the screw to pass through.

The idea is that the back will be able to incline, so I need to make holes so I can assemble the mechanism using some bolts. I clamped both pieces together to make sure that the holes in both pieces will be perfectly aligned and used the drill press to drill all the way through.

The third piece of the mechanism is the swing arm that allows the back to be adjusted. I’m going to use a large dowel to connect both arms. I used a Forstner bit to make a countersink hole the same size as my dowel, making sure not to go all the way through. I did a dry fit to check that everything was good and then used some glue to assemble the parts.

Before assembly, I sanded all the individual parts used 120-grit. After cleaning away all the sawdust, I pre-finished all the parts with teak oil. I simply used a clean cloth to rub in the finish and let it dry overnight.

For assembly, I used carriage bolts and nylon lock nuts. With my parts laid out, with the hooked pieces on the inside, I simply slipped in the bolts and then added lock nuts that I tightened all the way.

To attach the back slats, I clamped some stops to the edge of my workbench, and flipped the mechanism onto the slats, then push it to the very top edge. I could then use a leftover piece as a spacer and push everything up and in, and screw the first slat on. I repeated the same process on the opposite side, and could then use some spacer blocks to position the second slat, and screw it into place. I kept going like this, slat by slat, pushing everything into alignment and screwing on the slats, until I reached the end.

And now for the moment of truth… Looks like it works! Time to get a lounge cushion and enjoy the sun.