When you first start woodworking, you get a few different sets of clamps and think, alright this is great. Eventually your collection grows and you end up with clamps all over the place: hanging off tools, pilled in the corner, and pretty much anywhere you can stash them.

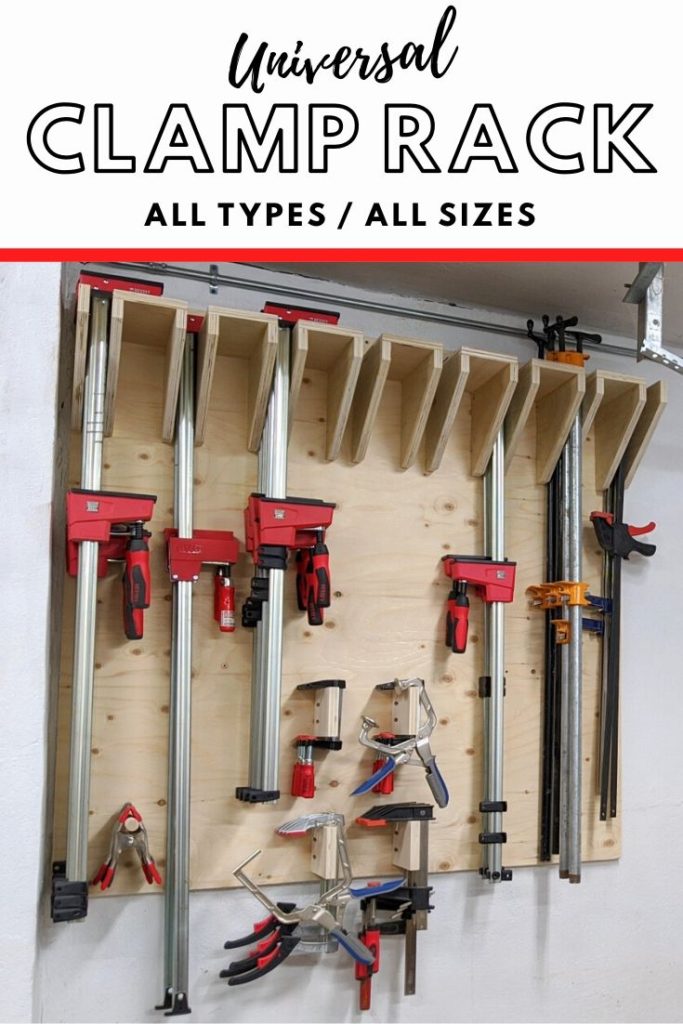

It’s time to build a suitable storage solution for all of my clamps. That’s why I’m going to build this space saving wall rack that can hold my entire clamp collection, with room to grow. The design is universal, so it can hold any type of clamp, including bar clamps, pipe clamps, parallel clamps, ratchet clamps, F-clamps, mini F-clamps, spring clamps, face clamps and pretty much any clamp you have! Let’s get started.

MY CLAMPS (affiliate links):

- Bessey parallel clamps https://amzn.to/3e0B6LW

- Pipe clamps https://amzn.to/2xa35rP

- One handed Bar clamps https://amzn.to/2JVSpA9

- Bessey ratcheting clamps https://amzn.to/2RetxHE

- Spring clamps https://amzn.to/2x7oces

- Mini F-clamps https://amzn.to/3bWSr6w

- F-clamps https://amzn.to/39GWSkw

- Kreg face clamp https://amzn.to/2VkBUD1

MATERIALS USED (affiliate links):

- 3/4 inch plywood

- 3/4 inch dowel rod https://amzn.to/2Xl1AC5

- 1-½” brad nails https://amzn.to/2xWt8Tj

- 1-½” wood screws https://amzn.to/2VbMdJt

- 1-¼” pocket screws https://amzn.to/2JLJSQa

- Glue https://amzn.to/2UN1HV9

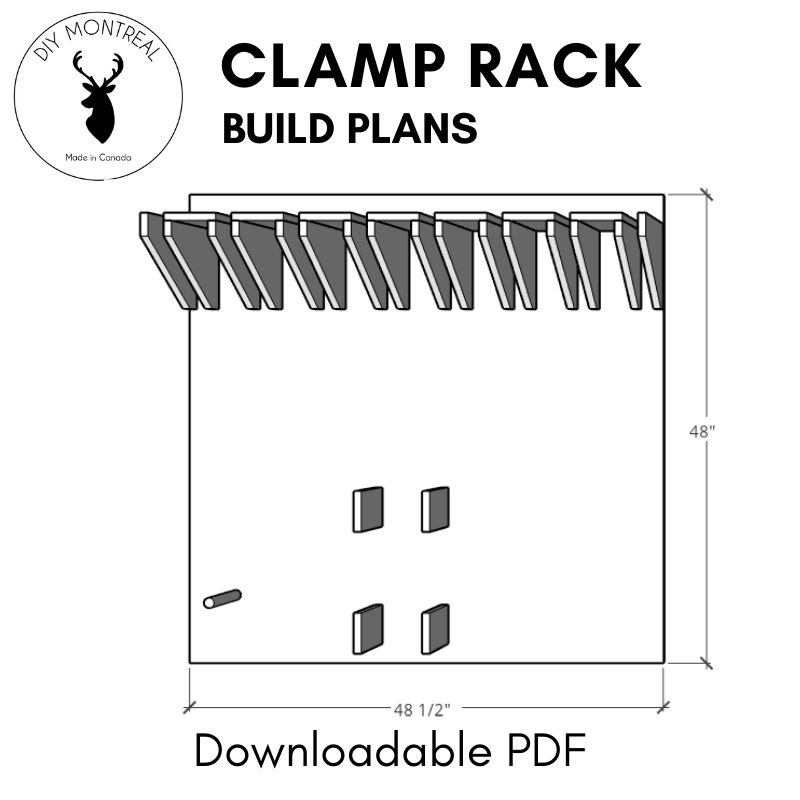

Get the Plans

How to Build a Clamp Rack for All Types and All Clamps Sizes

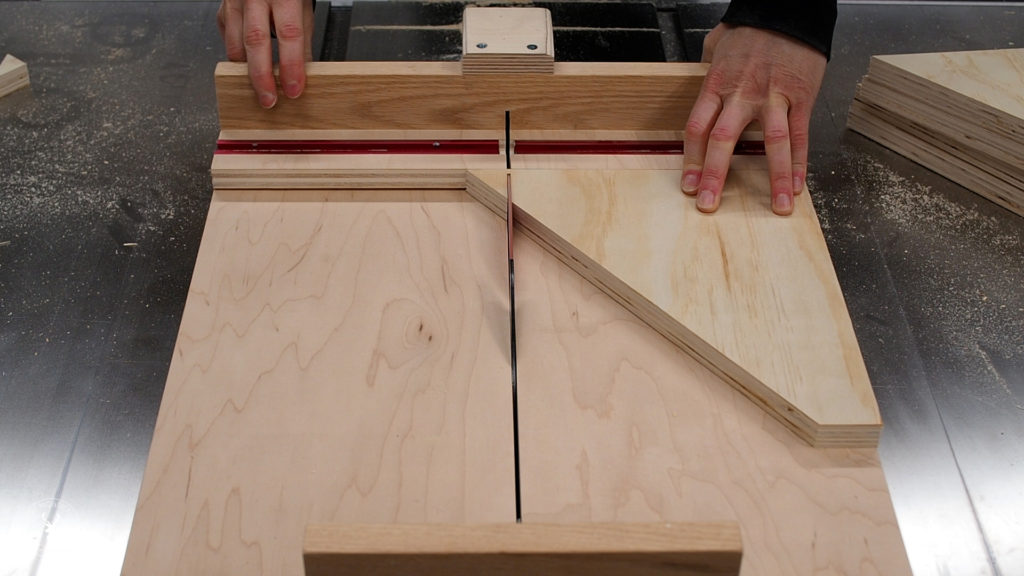

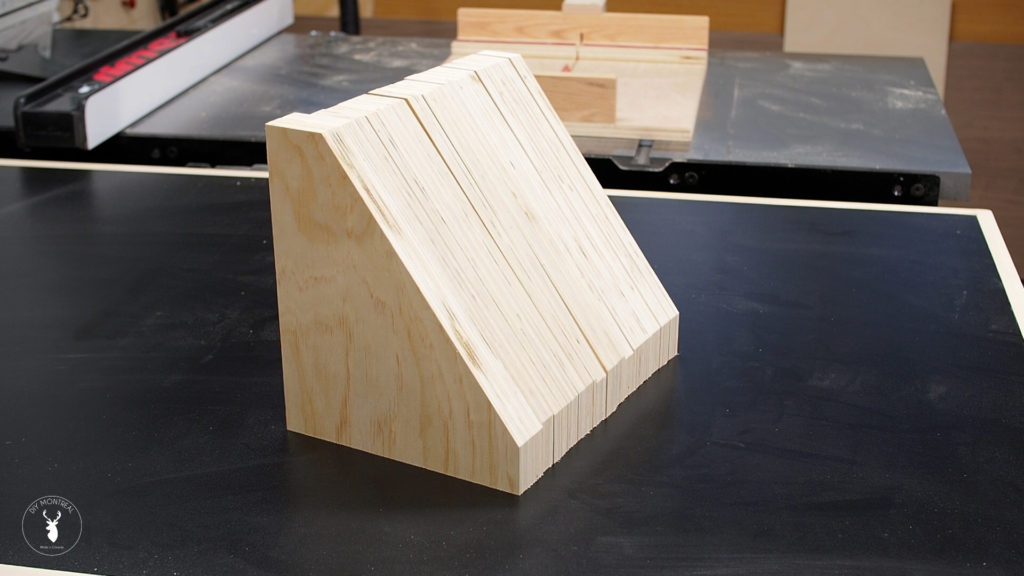

For this build, I’m using ¾ inch plywood. The first step is to build the brackets. For this I cut out 6 identical rectangles, and 2 wider ones that I’ll use for the two end brackets.

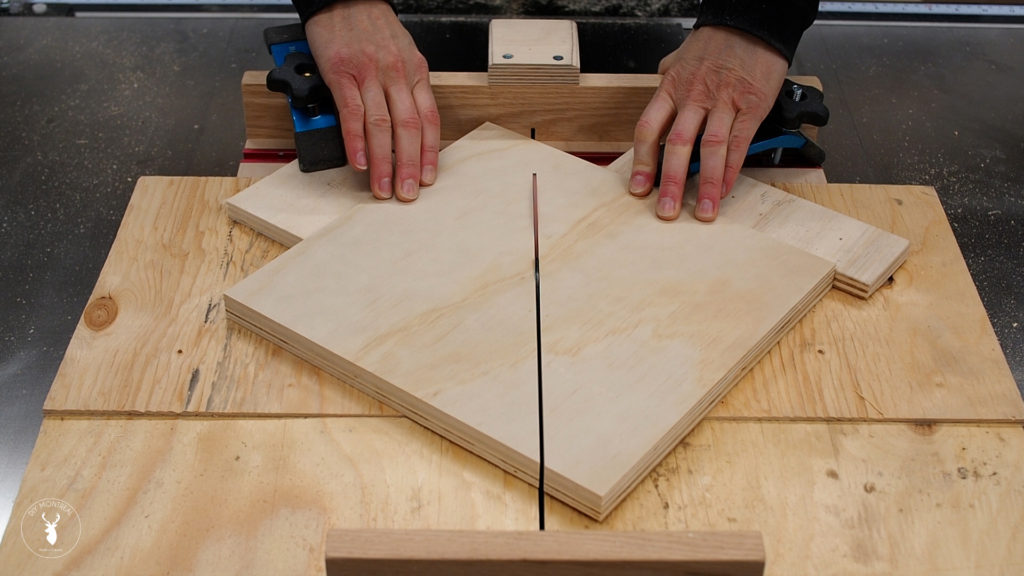

To cut the diagonals, I used my crosscut sled. I first traced the diagonal on one pieces and lined it up with the sled’s kerf line. I could then position 2 stops that I locked down to the sled. After that, I could just cut, drop in the next piece, and cut again.

The last thing I want to do before I start assembling is cut off the tips, and it worked out so I could just line up the edge with the edge of the sled to get consistent cuts on every piece.

When all the cuts were made, I ended up with 14 identical bracket pieces and 2 taller ones, that will go on each end of the rack.

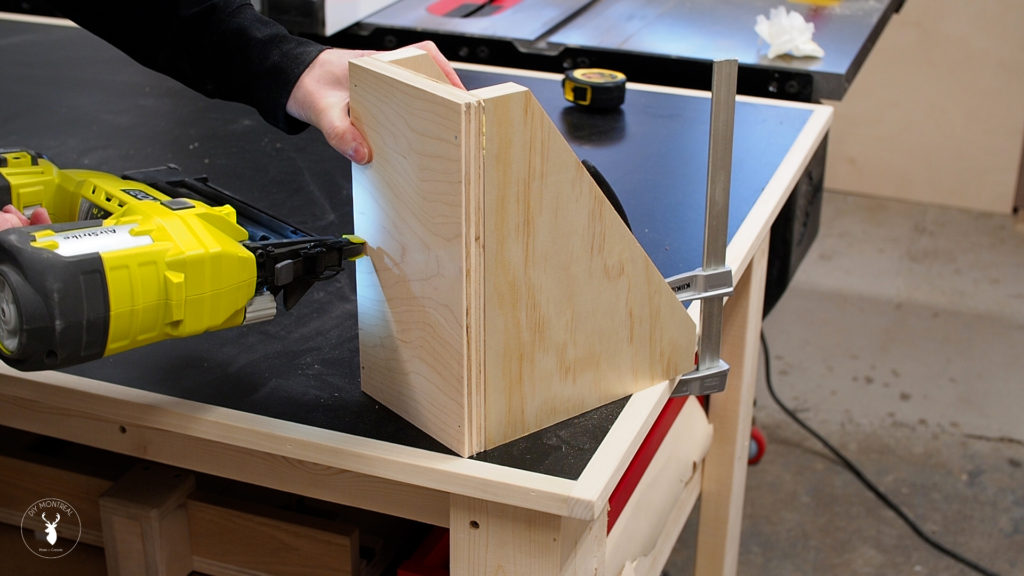

To assemble to brackets, I cut some extra pieces and these will be for the top of the brackets. I threw together a quick jig to help assemble the brackets, and clamped it to my workbench for stability. I applied some glue and used a few brad nails to secure the top panel. I then repeated this to make all 7 brackets.

I’m going to use a large backer board to mount the clamp rack to the wall, and this is so I can add extra holders for smaller clamps once the rack is already up. I used a large drywall square to mark the cuts, which I then made with my track saw.

I screwed together a couple off-cuts of a 2 x 4 to use as spacer blocks for assembly. I clamped down one of the blocks to my assembly table and lifted the backer board into place. I then clamped the board to the blocks to hold it upright without falling over.

I started by attaching one of the end brackets, right up against the outer edge. I applied glue, then temporarily secured it from behind using a few brad nails. I then used a small spacer block so I could just drop in the next bracket, again using glue and brad nails to attach it.

I kept going along the row, using the spacer and positioning the next bracket, until I reached the end of the row, and attached the other end bracket, again using glue and a few brad nails.

With all of the brackets temporarily secured, I attached every bracket with screws, after first making countersunk pilot holes.

I picked a spot in my shop to mount the rack to the wall and helped support it while I drilled pilot holes into my concrete walls using a masonry bit. I then attached the rack to the wall using concrete screws (for framed walls, screw into the studs).

Having storage for my long clamps is great, but I still have several smaller clamps that need a home, so I’m going to cut up some small blocks that will serve this purpose. I used my pocket hole jig to make a couple pocket holes, and mounted the blocks to the backer board. I determined the positioning visually guided by the space I had leftover after all of my longer clamps were hung.

The other addition I want to make is adding a simple dowel to hold my spring clamps. I drilled a hole through the backer board and slipped in the dowel after applying a little glue. I like this easy solution because you can fit it between 2 long clamps, and it allows you to just slip the clamps on and off, and you can add as many as you need depending how large your collection is.

The beauty of this design is that you can really customize it to fit your clamp collection, both big and small. I hope I was able to provide you with a few ideas to build your own, and just a reminder that I do have plans available for sale if you want to check those out!