With all of us spending more time at home this year, I find myself spending time in the kitchen and cooking more than ever before. That why I decided to dedicate this year’s DIY-holiday-gifts-you-can-make-out-of-wood edition to gifts for the kitchen.

Update! Just posted the 2021 holiday gifts edition here: https://www.diymontreal.com/woodworking-gifts-you-can-make/

— Watch the video — // — Subscribe to my YouTube channel —

DIY Gift Idea #1: Paint Dipped Spatulas

Tools & Materials used

- Hardwood such as maple, beech, or olive

- Bandsaw or jigsaw

- Sander

- Drill

- Mini sanding block

- Paint

- Painter’s tape

- Foam brush

- Butcher block conditioner

I had some leftover thin ash wood boards from my mid-century nightstand project, so I went with ash to make my spatulas out of convenience. That being said, I you might want to consider beech or maple, or even olive wood to make wooden spatulas.

I made 3 spatula designs that I dubbed the following: Angled spatula, Crepe spatula and Large spatula.

I fist planed down my wood to thickness: 7mm for the angled and crepe spatulas; 10mm for the large spatula. I then traced out the spatulas on my wood blank using a mock-up I made, but you can download my free printable spatula templates HERE.

I used my bandsaw to cut out the rough forms. It’s okay to stay outside the lines here and just get close to them. The rest of the work will be done with a sander.

Before I started shaping them further, I made a hole using a ¼ inch bit in all of the handles.

Using my bench sander, the first step was to eliminate any tool marks and sand up to the line all around to refine the rough shapes.

With that done, it was time to refine them. The angled spatula got a 45 degree chamfer on the tip just by holding it up against the belt sander on an angle.

The crepe spatula got rounded over, sort of like a beaver tail, until the outer edges are really thin. I also rounded over the edges of the handle.

For the large hefty spatula, I started by rounding over all of the edges slightly to make it more comfortable to handle. I then focused on shaping the tip of the spatula by slowly grinding down each side on a slight angle, until I had a thin tip, kind of like a wedge.

Now while they were in pretty good shape at this point, I gave them a good hand sanding to refine the shapes even further. This is how you really get those curves nice and smooth and make them look professional.

After sanding up to 220-grit, I wasn’t quite done yet. You’ll want to spray them with water at this point to raise the grain so they don’t get all rough the first time you wash them. Let them dry and hit them again with 220-grit paper.

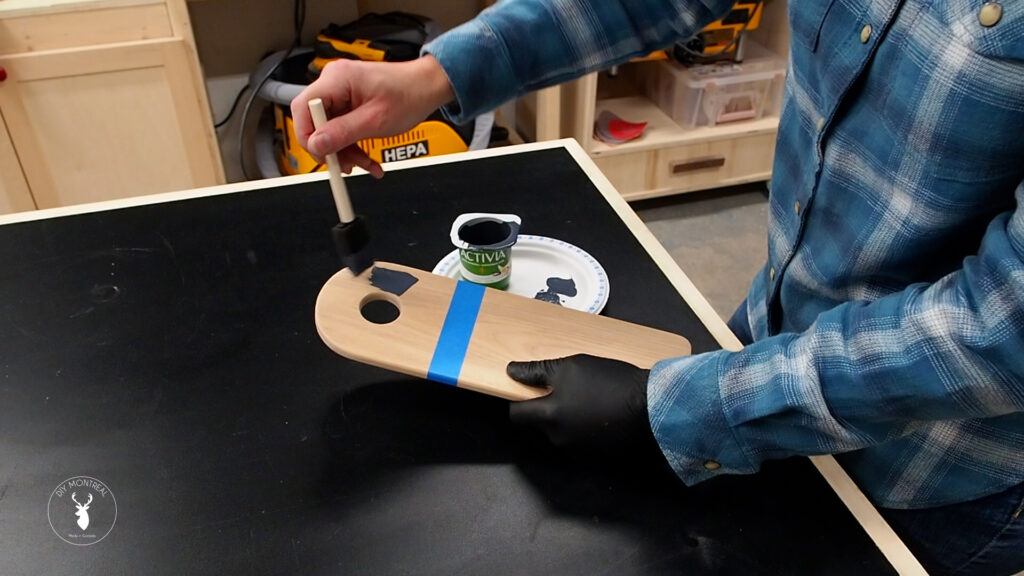

To give them a little style, I applied some painter’s tape around the mid-section and applied 2 coats of paint to the handles. This is just regular latex wall paint I had leftover.

Once dried, I could remove the tape and check that I got a nice crisp line. It’s important to really press down on the tape to get a nice seal before applying the paint. The last step is to apply some butcher block conditioner, let it sit for 20 minutes, and then rub it off.

DIY Gift Idea #2: Decorative Charcuterie Board

This idea makes a great gift when combined with the paint dipped spatulas. It can be used as a charcuterie board, or even just kitchen décor by propping it up against the backsplash.

Tools & Materials used

- Ash wood

- Forstner bit

- Compass

- Roundover bit

- Sander

- Paint

- Painter’s tape

- Foam brush

- Butcher block conditioner

I again used my leftover Ashwood and planed it down to about 11 mm. Next, I cut a blank that’s 10 inches long and 4 inches wide. And yes, I use both mm and inches. Sorry.

I marked 2 inches from the side and from the top, then traced a semi-circle using a compass set to approx. 2 inches so that the semi-circle would touch the edges. On the other end I used a small bottle cap to trace the rounded corners.

I drilled through on the marking using a 1-¼ inch Forstner bit, and then it’s back to the bench sander to shape the edges.

I slowly sanded away the excess wood using a circular motion until I reached the lines and was left with the shape I had traced out.

Next, I used a small roundover bit to round over all the edges. Then came the inevitable sanding, sanding up to 220-grit, then water popping to raise the grain, then sanding again.

Just as before with the spatulas, I applied some painter’s tape to get a crisp line, then painted the top part with a foam brush. I applied 2 coats and let it dry.

Once dry, I applied some butcher block conditioner to the wood. Oh and don’t be afraid to get it on the paint, you can rub it over the entire board.

DIY Gift Idea #3: Christmas Tree Serving Board

This next DIY gift has to be my favorite: a festive Christmas tree shaped serving board.

Tools & Materials used

- Walnut and ash wood

- Water resistant glue

- Parallel clamps

- Orbital sander

- Bandsaw

- Utility knife

- Butcher block conditioner

- Cutting board feet

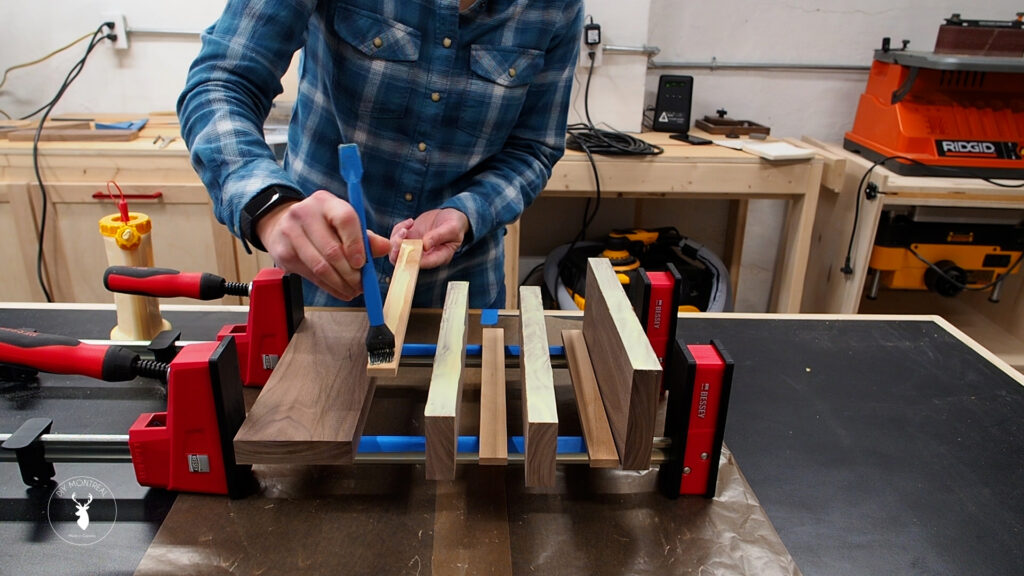

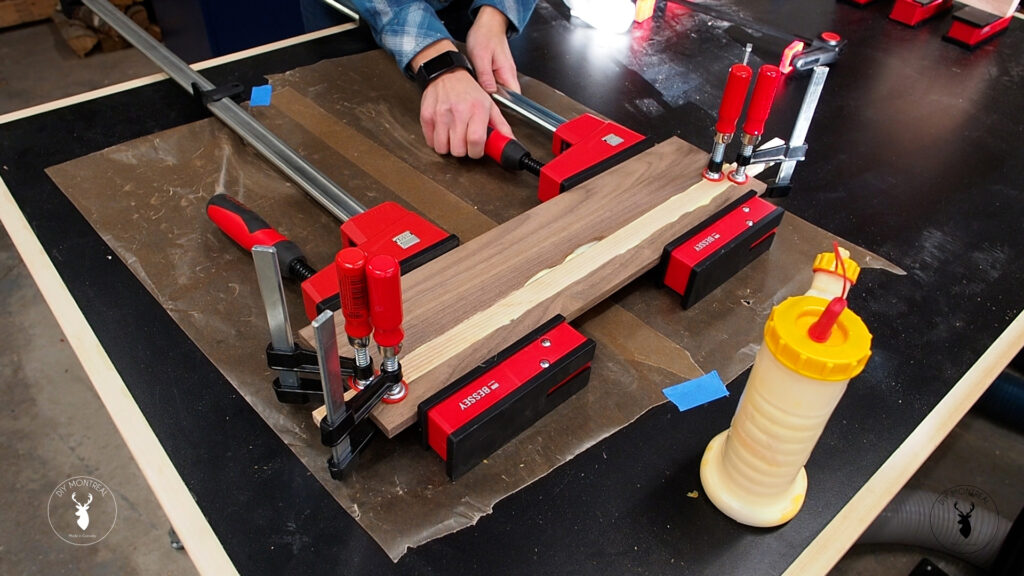

I cut 4 pieces of walnut and 3 strips of ash that I’ll glue up into a panel. All the pieces were roughly 7/8th of an inch thick and 13-14 inches long. The top and bottom pieces of walnut were roughly 4 inches wide, while the middle ones were 2-1/2 inches. As for the strips of ash, they are 3/8th wide.

I laid them out and got ready for glue up. This board will get washed so you’ll want to use water resistant glue.

Okay so after letting the board dry in the clamps, it was too wide to send through the planer, so I just sanded down both sides until it was flat.

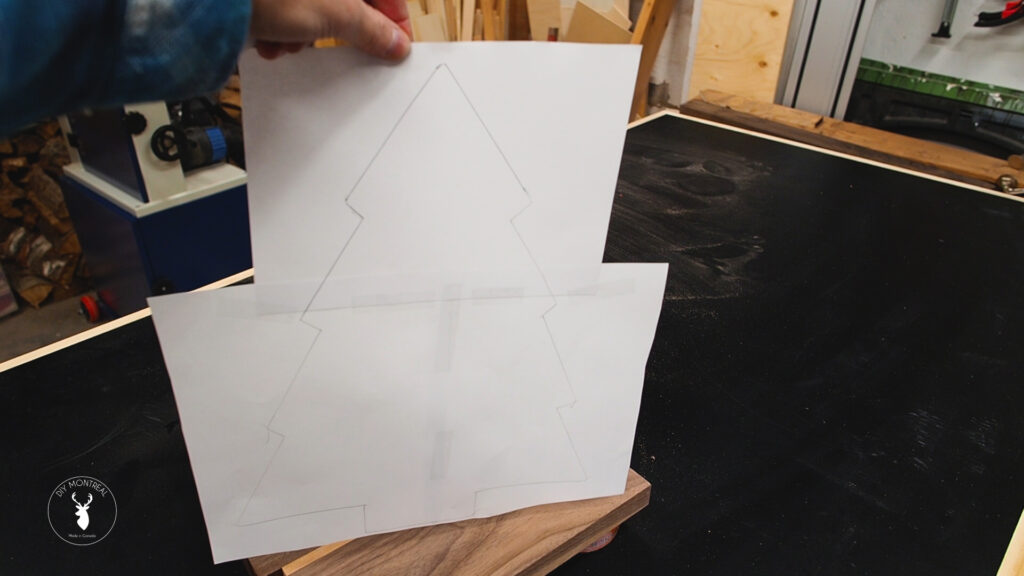

I traced an outline of a Christmas tree onto a sheet of paper. The overall dimensions of my tree are 13 inches tall with the base of the tree being 10 inches wide.

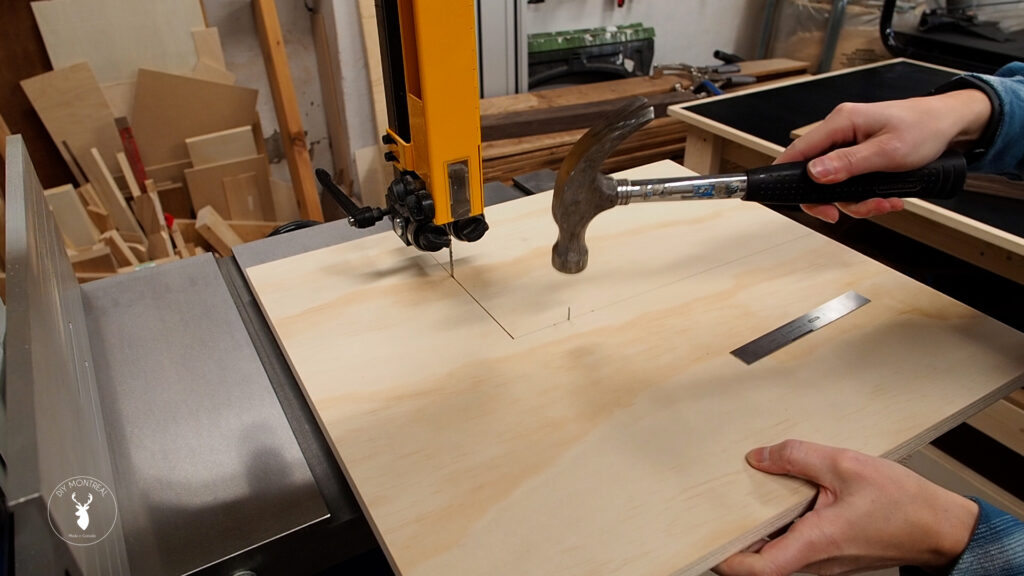

I laid the stencil on top of my board. Instead of laying it straight, I decided to put a bit of an angle on it, then used a glue stick to temporarily stick it in place. I could then use a utility knife to cut out the tree and score the board, ultimately transferring the outline onto it, which meant that I could then remove the stencil.

Here’s where the bandsaw comes in handy but a jigsaw could be used for this instead. I cut out the tree, following the scoring I had made.

I then used my orbital sander to clean up the bandsaw marks. I sanded everything up to 220-grit, making sure to break all the sharp edges too. Just as before, I sprayed it down with water to raise the grain, the let it dry before the final sanding.

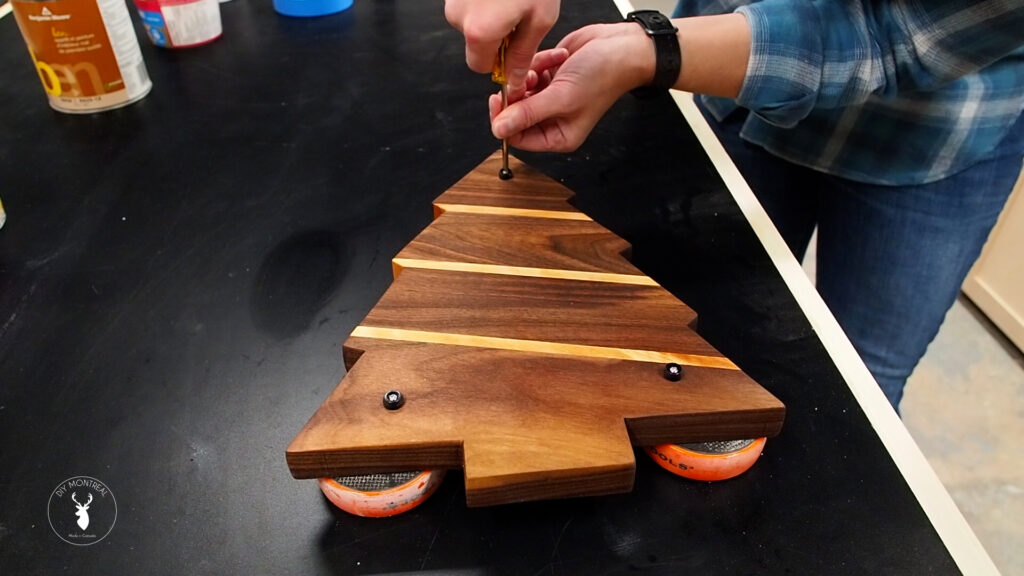

I applied a liberal amount of butcher block conditioner and massaged it into all the pores then let it sit for 20 minutes and buffed it off.

The last detail to make this serving board complete; I’m adding a few rubber cutting board feet underneath. And that’s it! I really love how this one turned out.

DIY Gift Idea #4: Round Walnut Coasters

Ah, wooden coaters. A classic woodworker’s gift. But if you really want to impress them, make them round wood coasters!

Tools & Materials used

- Walnut & ash wood

- Bandsaw

- Mini sanding block

- Water-resistant glue

- Parallel clamps

- Mini F-clamps

- Double-sided Speed Tape

- Denatured alcohol

- Osmo Polyx-oil

First I started by resawing some walnut down to about 3/8ths of an inch thick. Alternatively, you could buy some half inch wood and plane it down or just make thicker coasters.

I made a really simple pattern alternating a 3 inch strip of walnut, a 3/4 inch strip of ash and another 1-1/2 inch strip of walnut. but you can go crazy here and make any pattern you want. Each strip was about 18 inches long, with the ultimate goal being to make four 4-inch round coasters.

I used some mini F-clamps to keep everything as flat as possible during the glue-up. After removing the clamps, it felt flat enough that I could just give it a good sanding to flatten it out.

Next I cut 4 even-sized blanks using my miter gauge. I want 4 inch round circles, so I’m making my blanks slightly oversized at about 4-½ inches.

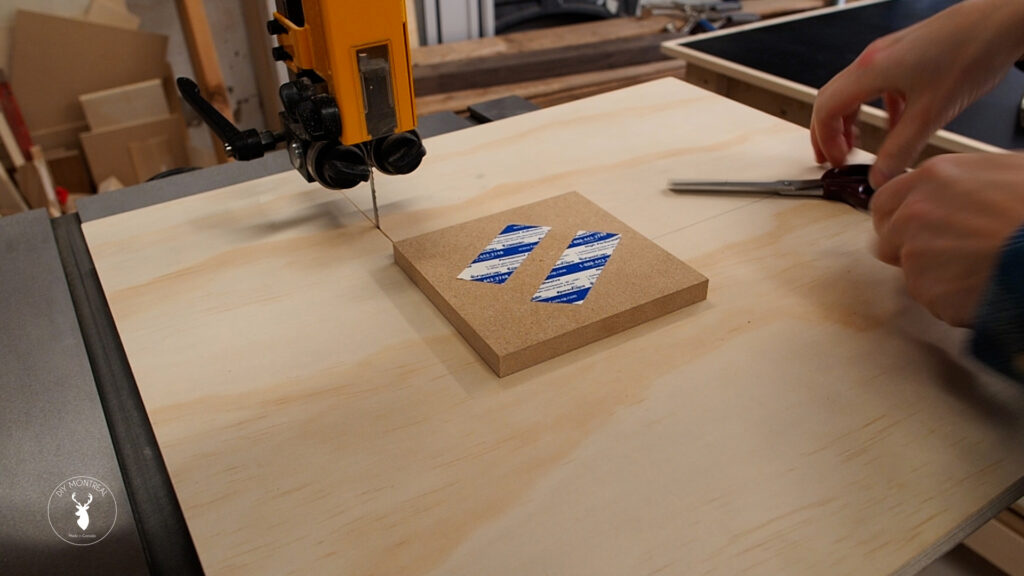

To cut the circles I’m going to use my bandsaw circle cutting jig. It’s a really simple jig and if you want more details, be sure to check out my circle cutting video where I demonstrate 4 ways to cut circles. I measured 2 inches from the blade and inserted a pivot pin to make 4 inch circles.

I didn’t want to have to make any holes in my coasters, so I used a scrap piece of MDF as a dummy. After finding the center, I mounted it to the pivot pin. I could then simply use some double-sided Speed Tape to mount the blank to the dummy.

I fired up the bandsaw and pushed the jig into place until it stopped, then rotated the piece around the pin until I had my first circle. After that I was able to just reuse the same tape for the next piece.

All that was left at this point is a bunch of sanding, including rounding over the edges. Before applying finish, I like to clean them off using denatured alcohol to remove all the sawdust.

I chose to finish them with Osmo Polyx-oil. It’s just so easy to apply: rub it in and wipe it off, and gives a really silky natural finish.